Description

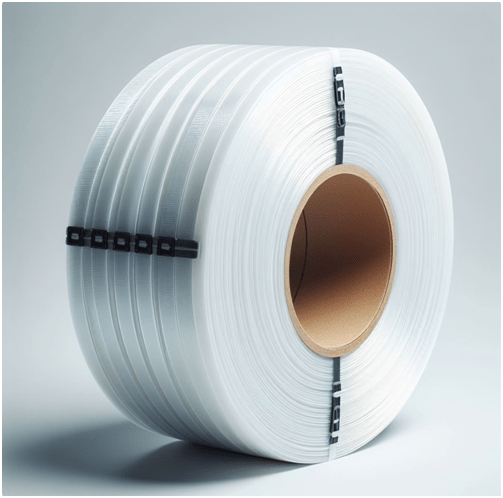

A Strap roll (also referred as Pallet roll) typically refers to a roll of strapping material used for bundling, reinforcing, or securing items during shipping, storage, or transportation. Strapping material, commonly made from materials like plastic (polypropylene or polyester) or metal (steel or stainless steel), is available in the form of rolls wound onto a core.

A strap roll typically refers to a roll of material used for strapping or binding items together for various purposes such as packaging, shipping, or securing loads. Strap rolls come in different materials, sizes, and configurations depending on the specific application.

Plastic strapping rolls are lightweight and flexible, making them suitable for securing lighter loads or items where flexibility is required. They are commonly used in industries such as logistics, distribution, and agriculture for bundling cartons, pallets, or packages.

Overall, strap rolls provide a versatile and reliable solution for securing and stabilizing loads, preventing damage, shifting, and tampering during transit or storage

Usage / Applications

Plastic strap rolls, commonly made from materials like polypropylene (PP) or polyester (PET), find numerous applications across various industries due to their versatility, strength, and cost-effectiveness. Here are some common applications and usages of plastic strap rolls:

Pallet Strapping: Plastic strap rolls are extensively used for securing goods on pallets in warehouses, distribution centers, and manufacturing facilities. The straps are wrapped around the palletized load and tensioned using strapping tools or machines to provide stability and prevent shifting during transportation.

Shipping and Logistics: Plastic strap rolls are essential for bundling and securing packages, cartons, and boxes for shipment. They are used in conjunction with strapping machines or manual tensioners to create tight and secure bundles, ensuring the safe transit of goods.

Retail Industry: Plastic strap rolls are used in the retail industry for bundling products, such as newspapers, magazines, and bulk items like beverages or consumer goods, for distribution and display purposes.

Brick and Tile Industry: Plastic strap rolls are employed in industries dealing with heavy materials like bricks, tiles, and blocks. They are used to secure these materials onto pallets or skids for safe transportation to construction sites or distribution centers.

Baling and Recycling: Plastic strap rolls are used in recycling and waste management facilities for baling recyclable materials such as cardboard, paper, plastic, and metal. The straps help to compact and secure the bales for efficient storage, handling, and transportation.

Food and Beverage Industry: Plastic strap rolls are utilized in the food and beverage industry for bundling and securing bulk packaging, such as crates of bottled beverages or cases of canned goods, for distribution to retailers or wholesalers.

Furniture and Appliance Industry: Plastic strap rolls are used for securing furniture items, appliances, and large household goods during transit. They help to prevent damage caused by movement and shifting during transportation and handling.

Textile Industry: Plastic strap rolls are employed in the textile industry for bundling and securing rolls of fabric or carpets for storage, transportation, or distribution to retailers.

Horticulture and Agriculture: Plastic strap rolls find applications in horticulture and agriculture for bundling and securing plants, trees, and agricultural produce such as fruit crates or vegetable boxes for transportation and sale.

DIY and Home Improvement: Plastic strap rolls are used by consumers for DIY projects, such as bundling items for storage, securing items for moving, or even for creative crafting purposes.

Overall, plastic strap rolls are versatile packaging materials that offer strength, flexibility, and reliability for a wide range of applications across various industries.

Specifications

The specifications of plastic strap rolls can vary depending on factors such as the material type, width, thickness, length, and tensile strength. Here are some common specifications to consider when selecting plastic strap rolls:

Material Type: Plastic strap rolls are commonly made from polypropylene (PP) or polyester (PET) materials. Each material offers different properties and advantages. For example, PP straps are lightweight and economical, while PET straps offer higher tensile strength and are more suitable for heavy-duty applications.

Width: Plastic strap rolls come in various widths to accommodate different packaging needs. Common widths range from 6 mm (0.24 inches) to 19 mm (0.75 inches) for light-duty applications, and from 12 mm (0.47 inches) to 32 mm (1.25 inches) for heavy-duty applications.

Thickness: The thickness of plastic strap rolls, also known as gauge or mil thickness, is an important factor determining the strap’s strength and durability. Common thicknesses range from 0.5 mm (0.02 inches) to 1.3 mm (0.05 inches) for light-duty straps, and from 0.8 mm (0.03 inches) to 1.5 mm (0.06 inches) for heavy-duty straps.

Length: Plastic strap rolls are available in various lengths to suit different packaging requirements. Roll lengths typically range from several hundred meters to several thousand meters, depending on the roll size and application.

Tensile Strength: The tensile strength of plastic strap rolls refers to the maximum load or force the strap can withstand before breaking. It is usually measured in pounds per square inch (psi) or kilogram-force per square millimeter (kgf/mm²). Higher tensile strength straps are suitable for securing heavier loads or for applications requiring greater durability.

Core Size: Plastic strap rolls are wound onto cores, which come in different sizes depending on the strapping machine or tool being used. Common core sizes include 200 mm (7.87 inches), 280 mm (11.02 inches), and 406 mm (16 inches).

Surface Finish: Plastic strap rolls may have different surface finishes, such as embossed or smooth, which can affect the strap’s friction and handling characteristics.

Color: Plastic strap rolls are available in various colors, including white, black, blue, green, and yellow. The color choice may be based on industry standards, branding preferences, or specific application requirements.

These specifications help users select the appropriate plastic strap rolls for their particular packaging needs, ensuring optimal performance and efficiency in securing and stabilizing loads during transportation and storage.